Facilities

• We have an able administration and requisite infrastructure to ensure compliance to all statutory and regulatory requirements of production, along with compliance to requirements of importing country

• The manufacturing facility is situated near the town of Karjan, 35 kms from Vadodara City in the province of Gujarat, in a green belt geography on the State Highway easily accessible from Ahmedabad and Mumbai. Nearest ports are Mundra and Hazira in Gujarat.

• The unit is spreads on a total land area of 4 acres. The building is in R.C.C. construction area and divided into processing areas, production halls and distinct storage warehouses for packing material, ingredients and finished products. There are basic sanitation facilities with regards to hygiene.

• There is sufficient office space for individual departments, along with training and conference rooms. Scientifically designed layout ensures compliance to safety rules, ease of flow of material, with minimum movement of manpower and also allow allergen handling and management.

• Cemented flooring of exterior grounds and Kota stone flooring inside the facility allows efficient housekeeping; glazed tiling on walls up to 8 ft to effectively forbid pest movement.

• Exhaust fans along with ample height of ceiling to reduce the effects of summer time and humidity. Process areas provisioned with special refractory flooring to withstand heat, abrasion and maintenance.

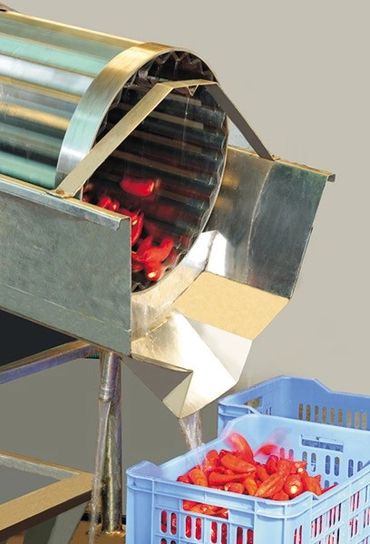

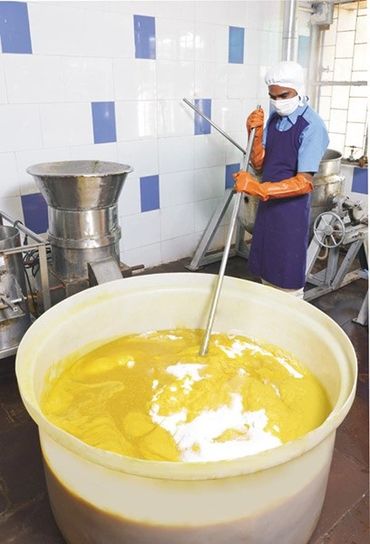

• Dealing in vegetarian products, the unit furnished with well-maintained food processing equipment and packaging machinery, and material handling equipment for example – bottle washers, sorting conveyers, filling lines, steam jacketed kettles, mixers and blenders, fruit pulpers and grinders, metal detectors and shrink tunnels, etc.

• We have a well maintained and functional effluent treatment plant, goods lift or elevator and surveillance system. We have pollution board permit and registration for disposal of effluent through CETP. Provisions have been made for uninterrupted availability or supply of utilities like steam, compressed air, potable water, electricity and internet connectivity.

• An IPQC laboratory with skilled QC chemists and adequate instruments is there from the beginning for the purpose of testing incoming raw material and in-process product batches.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.